DESCRIPTION

Brake system is hydraulically operated, utilizing a tandem master cylinder and a Teves power brake unit. Front disc brakes consist of rotors attached to wheel hubs, and single piston floating caliper assemblies attached to steering knuckles. The disc brake pads are equipped with wear indicators that create a pulsation in the brake pedal when the pads are worn. Rear brakes are leading trailing shoe/drum type, using a dual piston wheel cylinder. Parking brake cable actuated, operating secondary shoes of rear brake assemblies. Pressure regulator valves for rear wheels mount to power brake unit.

ADJUSTMENT

FRONT DISC BRAKE PADS

Front disc brakes are self-adjusting, therefore, no adjustment in service is required.

REAR DRUM BRAKE SHOES

Raise and support rear of vehicle, release parking brake. Use a brake spoon, tighten rear star adjuster until wheel can no longer be turned by hand. Loosen star until wheels are just free to turn.

PARKING BRAKE

With rear brake shoes properly adjusted, pull parking brake handle to second notch. Tighten parking brake adjusting nut rear wheels can just be turned by hand, then tighten lock nut. Release handle and ensure both rear wheels rotate freely.

PRESSURE REGULATOR VALVE

Operation Test - Place hand around pressure regulator. Depress brake pedal relatively hard. Release pedal; listen and feel for a slight "knock" in each regulator. This is the piston returning in regulator.

Pressure Test - 1) Use two pressure gauges that will record at least 1400 psi. Hook one gauge to left rear wheel cylinder. Attach other gauge to right front caliper cylinder. Bleed both hoses through bleeder gauges. Operate pedal vigorously several times.

2) Depress brake pedal until gauge on right front caliper reads 497 psi at the same time the gauge hooked to the left rear wheel cylinder should read 384 psi.

3) Continue depressing pedal and hold it in position when right front gauge reads 1400 psi, left rear wheel cylinder gauge should read between 768-862 psi. Repeat procedure to check other side. Replace any regulator that does not meet specifications outlined here.

HYDRAULIC SYSTEM BLEEDING

Fill master cylinder reservoir with brake fluid and maintain level throughout bleeding operation. Attach a hose to bleeder screw, and immerse end in a container partially full of brake fluid. Open bleeder screw approximately one-half turn, depress brake pedal, close bleeder screw, and slowly return pedal. Continue operation until air bubbles are no longer seen discharged fluid. Bleeding sequence is right-rear, left-rear, right-front, left-front.

REMOVAL & INSTALLATION

FRONT DISC BRAKE PADS

Removal - Raise and support front of vehicle and remove wheel and tire assembly. Pull spring locks out of retaining pins, drive retaining pins out toward outside of vehicle, and remove cross spring. Use a suitable tool (P 86), remove inboard brake pad. Pull mounting frame and brake cylinder outwards until outboard pad can be removed

Installation - Press piston to bottom of travel in cylinder and floating frame. NOTE - Level in master cylinder reservoir will rise. Siphon off sufficient fluid to prevent overflowing. Ensure machined portion of piston face makes a 20° angle to lower caliper wall. Install disc pads by reversing removal procedure.

FRONT DISC BRAKE CALIPER

Removal - With wheel and tire assembly and disc brake pads removed, disconnect hydraulic line from caliper. Remove bolts securing caliper to steering knuckle and remove caliper.

Installation - Reverse removal procedure and bleed hydraulic system.

FRONT DISC BRAKE ROTOR

Removal - With wheel and tire assembly removed, remove caliper. NOTE - Do not disconnect hydraulic line unless necessary. Remove screw securing rotor to wheel hub and withdraw rotor.

Installation - Reverse removal procedure and bleed hydraulic system if necessary.

REAR BRAKE DRUM

Removal - Pry off grease cap. Remove cotter pin, castle nut, hex nut, and washer. Pull off brake drum making sure that inner race of outer bearing is not lost.

REAR BRAKE SHOES

|

| Fig. 1 Exploded View of Rear Brake Assembly |

Removal - With brake drum removed, disconnect lower spring by removing from primary shoe. Remove shoe vibration cups, springs, and pins. Remove primary shoe from backing plate, disconnect parking brake cable from lever, and remove secondary shoe and parking brake lever assembly.

Installation - Reverse removal procedure and not the following: Before installing secondary brake shoe, make sure that rear wheel cylinder piston is positioned so that web face outward and opening inward. Ajust brakes and bleed hydraulic system if necessary.

REAR BRAKE WHEEL CYLINDER

Removal - Depress brake pedal approximately 1.2" to close compensator bore in master cylinder, and hold in position using a suitable pedal support. Disconnect hydraulic line from cylinder and plug with rubber cap from bleeder screw. Remove bolts attaching wheel cylinder to backing plate. Remove cylinder by maneuvering out of backing plate

Installation - Reverse removal procedure and not the following: Make sure that rear piston is installed in wheel cylinder so that web faces outward and opening inward. Bleed hydraulic system.

|

| Fig. 2 Audi Fox Disc Brake Caliper Assembly |

MASTER CYLINDER

Removal - Siphon brake fluid from master cylinder reservoir. Disconnect hydraulic lines at cylinder, remove nuts attaching master cylinder to power unit, and remove master cylinder.

Installation - Reverse removal procedure and not the following: Make sure "O" ring is installed between master cylinder and power unit. After installing master cylinder, bleed hydraulic system.

OVERHAUL

FRONT DISC BRAKE CALIPER

Disassembly - Remove disc pads and pry mounting frame and piston assembly off floating frame. Remove brake cylinder and guide spring from floating frame. Remove clamp and dust cap from brake cylinder, then withdraw piston. NOTE -If necessary, apply compressed are to fluid inlet. Remove seal from cylinder.

Cleaning & Inspection - Thoroughly clean all parts in alcohol. Check all parts for rust, corrosion, or other damage; replace parts as necessary. NOTE - Manufacturer recommends replacing rubber parts whenever caliper has been disassembled.

Reassembly - Apply a thin coat of ATE brake cylinder paste (or equivalent) to cylinder, piston and seal, and reassemble. Place guide spring in groove of brake cylinder, then drive cylinder on floating frame with a brass mandrel. Place mounting frame in guide spring, then slide it on floating frame.

REAR BRAKE WHEEL CYLINDER

|

| Fig. 3 Exploded View of Rear Wheel Cylinder |

Disassembly - Remove rubber dust caps, then withdraw front and rear piston and seal assemblies. Remove seals from pistons. Remove bleeder screw and dust cap.

Cleaning & Inspection - Thoroughly clean all components in alcohol. Inspect cylinder and pistons for rust, corrosion, or scoring; replace parts as necessary. NOTE - Manufacturer recommends replacing all rubber parts whenever cylinder has been disassembled.

Reassembly - Reverse disassembly procedure and note the following: Pistons are not interchangeable. Install notched piston in front of cylinder so that it will engage primary shoe when installed on backing plate.

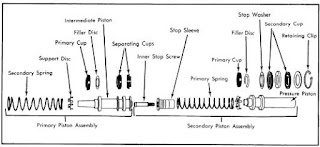

|

| Fig. 4 Master Cylinder Pinion Assembly |

MASTER CYLINDER

Disassembly - Remove "O" ring from master cylinder housing. Remove retaining ring and loosen piston stop screw, then remove both pistons from housing. Remove pressure valves and reservoir from master cylinder housing. Disassemble piston assemblies as necessary.

Cleaning & Inspection - Clean all parts in alcohol and check for rust, corrosion, or other damage; replace parts as necessary. Make sure compensating and filler holes are not plugged.

Reassembly - Reverse disassembly procedure and note the following: Make sure pressure and intermediate piston cups are installed correctly. See Fig. 4. Use new "O" ring on master cylinder between cylinder and power unit.

POWER BRAKE UNIT

NOTE - No information available for Overhaul of power brake unit.

Advertisement:

0 comments:

Post a Comment

Note: Only a member of this blog may post a comment.