Models Covered:

- 280 Models (1968-72)

- 300 Models (1968-72)

DESCRIPTION

Axle assembly is of split case design with hypoid type gears in which centerline of drive pinion is mounted below centerline of ring gears. Remove case half of permits inspection and service of differential. All adjustments, except pinion bearing preload, are performed using shims. Pinion bearing preload is set using a collapsible spacer. Some models use a limited slip differential, either as standard or optional equipment.

AXLE RATIO AND IDENTIFICATION

All models 1968-72 Mercedes Benz 280 and 300 models use the split case rear axle with single pivot type rear suspension. Some models also have limited slip differentials. To determine axle ratio, divide number of ring gear teeth by number of pinion gear teeth.

REMOVAL AND INSTALLATION

AXLE SHAFT AND BEARINGS

Removal - 1) With vehicle raised and rear wheels removed, remove brake caliper and rotor, then remove parking brake shoes and brake backing plate. Attach a suitable tool (100 589 02 33 00) to flange of rear axle shaft and knock shaft out of supporting tube.

2) Insert axle shaft into suitable assembly plate (136 589 05 31 00) and remove slot nut using suitable slot nut spanner (136 589 09 07 00). Pull of grooved ball bearing of self aligning bearing with suitable puller (136 589 20 33 00). Press sealing ring out of brake backing plate and support tube.

Installation - 1) Coat circumference of sealing ring with sealing compound and press into brake backing plate. Coat contact surface of sealing ring with molybdenum disulphide paste and carefully slide backing plate in position. Press grooved ball bearing or self-aligning bearing on rear axle shaft. Place lock washer with flange against inner race of bearing and make sure that it is perfectly seated. Install and tighten slot nut.

2) Coat new seal with sealing compound and install support tube. Fill cavity between inner and outer sealing rings and bearing seat with bearing grease. Install axle shaft into support tube. NOTE - When installing self-aligning bearings, insert fixture 111 589 08 63 00 between brake backing plate and flange of axle shaft. This will locate bearing in its correct position. Screw bake backing plate to support tube and install brake shoes, rotor and caliper. Check axle oil level.

PINION FLANGE AND SEAL

Removal - 1) Drain oil from rear axle and place supporting tubes in horizontal position. On models with air suspension disconnect and fold down torsion bar. Loosen exhaust system joint and remove. Remove shield plate and loose universal shaft intermediate bearing on frame; do not remove bolts completely. Loosen universal clamping nut.

2) On all models, mark propeller shaft for proper installation and disconnect at pinion flange. Unscrew flange slot nut using suitable spanner wrench (111 589 00 07 00) and holding flange with suitable tool (111 589 02 07 00). Pull flange from pinion. Remove seal from drive axle housing.

Installation - 1) Coat new seal circumference with sealing compound and inner into housing. Coat mating surface flange with molybdenum sulphide paste and slide flange drive pinion, noting markings for correct alignment. While holding flange, tighten slot nut until a torque of 23-29 INCH lbs. (20-25 cmkg) is required to rotate entire drive axle assembly at pinion flange. NOTE - When checking torque, ensure that support tubes are horizontal and that brake pads and shoes do not drag. If torque exceeds specifications, a new collapsible spacer must be installed.

2) Secure slot nut and install propeller shaft. Slightly tighten joint intermediate bearing on frame. Fill drive axle with lubricant and move vehicle back and forth several times. Tighten clamping nut on propeller shaft and tighten intermediate bearing. On models with air suspension, mount shield exhaust system and reconnect torsion bar.

AXLE ASSEMBLY

Removal - 1) On models with air suspension, leave knob for control valve in "driving position" and raise vehicle. Bleed off all air from supply tank and check by finger pressure that rear bellows are free of air. Loosen hex bolts attaching supporting piston-to-thrust rods. Disconnect connecting rod for rear level control valve and remove ball pin. Remove torsion bar and proceed with balance of drive axle removal.

2) On all models, remove exhaust system. Remove heat shield, if equipped. Disconnect brake cable control on frame and compensating lever. Remove propeller shaft. On vehicles with conventional suspension, remove compensating spring and rear springs. On air suspension vehicles, unscrew supporting piston from radius arm and leave piston in bellows. On all models, disconnect brake hose from calipers.

3) Loosen radius arm-to-chassis mount. Unscrew bolts on front link of cross strut and remove front link. Loosen rear link and push cross strut toward rear. Loosen mounting of brake hold down on chassis by unscrewing nut inside vehicle under rear seat and pulling out bolt. Raise support tubes slightly and disconnect lower shock absorber mounts.

4) Raise support tubes until almost horizontal and attach suitable holding clamp (111 589 07 61) to rear axle to prevent tubes from drooping. Place jack with suitable holding fixture (111 589 05 61) under axle housing. Unscrew bolt on rubber mount of rear axle suspension carrier from inside trunk. Lower rear axle and remove from vehicle, making sure support tubes are not allowed to droop.

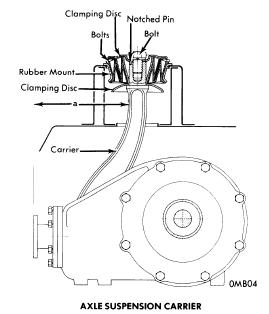

Installation - 1) Check that dimension "a" (see illustration) between pinion flange and rear axle suspension carrier is 6.22±.04" (158±1 mm) and that carrier is at right angles to left side support tube. Insert suitable conical installation mandrel (111 589 00 61) on rear axle suspension carrier, raise axle and guide carrier into rubber mounts. Correctly position clamping plate and screw in bolt. Install circlip, lower jack and tighten bolt. Remove holding clamp.

2) Install shock absorbers and attach cross strut with both links to carrier. Attach radius arm to chassis and reconnect brake lines. Bleed brakes. On vehicles with air suspension, attach supporting piston to radius arm and make sure set pin for locating piston is correctly mounted in radius arm. Also check seat of supporting piston in bellows. On conventional suspension models, install rear springs and compensating spring.

3) Mount lever for brake hold down to frame side member. Install propeller shaft and slightly tighten intermediate bearing nuts. Check axle oil level and lower vehicle. Move vehicle back and forth several times, then tighten clamping nut on propeller shaft and intermediate bearing nuts. Attach heat shield (if equipped) and install rear brake cables and exhaust system. Install torsion bar and adjust parking brake.

4) On vehicles with air suspension, place control valve lever in zero position and fill system with compressed air. Lower vehicle carefully. CAUTION - Vehicle does not have full ground clearance. Adjust rear ride height. On vehicles with conventional suspension, make sure rear axle tracks correctly.

OVERHAUL

DISASSEMBLY

1) Remove both struts and axle shafts. Unscrew nut of wedge screw which locks connecting bolt in axle housing. Pull rubber sleeve from housing. Loosen nut on connecting bolt and clamping screw on cover of axle housing. Knock connecting bolt out toward rear using suitable mandrel (180 589 08 39 00) and remove right side support tube. Loosen clamping screw and remove right side slip joint. Remove oil cooling pipe and unscrew left side support tube from housing. Remove differential.

2) Pull bearing outer race out of left support tube using suitable puller (108 589 01 33 00). Remove backlash shim from tube assembly. Unlock threaded ring and screw out of axle housing using suitable wrench (108 589 00 07 00). Knock outer race of bearing out of housing using suitable driver (108 589 00 43 00).

3) Remove slot nut securing pinion flange and press pinion out of housing using suitable press (111 589 12 61 00) complete with collapsible sleeve. Remove flange and unscrew from cover. Remove bearing from housing. Press rear bearing outer race out of axle housing using press tool. Remove shim. Pull outer race of front bearing out of housing using suitable tool (111 589 12 61 00). NOTE - This tool will pull race off over tapered rollers.

4) To disassemble case assembly, unscrew bolts attaching ring gear case and force gear off. Pull both bearing off case using suitable puller (187 589 05 33 00). On standard differentials, remove coil spring lock securing pinion shaft, knock out shaft and remove pinions with spherical washers, side gears with bearing ring and thrust washer. On limited slip differentials, knock out coil spring lock or plate spring and remove pinion shaft. Remove pinion gears with washers, then remove right side gear. Now remove left side gear and clutch discs.

REASSEMBLY AND ADJUSTMENT

Case Assembly (Standard Differential) - 1) Inspect all components for wear or damage and be sure to replace pinions, thrust washers, polyamide bearing ring and spherical washers which have run hot or seized. NOTE - An oversized polyamide bearing ring is available which will have to be matched .0008" (.02 mm) larger than bore in case.

2) Place thrust washer and polyamide bearing ring on side gear and insert into case. Insert other side gear in case. Insert pinions with spherical washers into case and insert suitable assembly mandrel (108 589 00 61 00) through case and pinions. Screw joint yoke to right side gear and rotate side gears using torque wrench. Side gears should have no backlash and require a torque value of 130-174 INCH lbs. (150-200 cmkg) to rotate. If torque value is not obtained. Insert thicker or thinner thrust washers as necessary to achieve torque.

3) Knock in new pinion shaft and secure with new coil spring lock. Carefully clean bore of ring gear and seat on differential housing. This process will be aided by heating ring gear to 140-158°F (60-70°C) and tapping lightly with rubber hammer. Insert and tighten ring gear bolts in a crosswise pattern. Press inner races of bearing on case using suitable sleeve (108 589 01 43 00).

Case Assembly (Limited Slip Differential) - 1) Inspect components for wear or damage and be sure to replace pinions, thrust washers and spherical washers which have run hot or siezed. Also, if friction discs need to be replaced it is recommended that the entire clutch pack be replaced. Place friction disc with lining on one side on side gear so lining faces contact surface of side gear. Coat five friction discs without lining and four friction disc with lining on bot sides with molybdenum disufphide paste and place on side gear in sequence of: without lining, with lining, etc.

2) Insert left side gear, without pressed-in nut, along with friction discs into case of ring gear end. Insert right side gear with pressed-in nut into case. NOTE - Make sure friction discs are arranged in correct sequence and that lugs of discs without lining engage in slots in case. Insert pinions with spherical washers into case and slide suitable assembly mandrel (108 589 00 61 00) through case, pinions and washers. Screw joint yoke to right side gear and rotate side gears using torque wrench. Side gears should have no backlash and require a torque of 217-304 INCH lbs. (250-350 cmkg) to rotate. If torque value is not obtained, insert thicker or thinner thrust washers as necessary to achieve torque.

3) Knock in pinion shaft and secure with new coil spring lock or plate spring. Carefully clean bore of ring gear and seat on differential housing. This process will be aided by heating ring gear to 140-158°F (60-70°C) and tapping lightly with rubber hammer. Insert and tighten ring gear bolts in a crosswire pattern. Press inner races of bearings on case using suitable sleeve (108 589 01 43 00).

Drive Pinion Depth - 1) With dial indicator plunger of device 116 589 00 23 00 depressed about .12" (3 mm) by gauge block 108 589 01 23 00 part 21, zero dial indicator. Press inner tapered roller bearing on drive pinion and place bearing outer race on roller cage of bearing. Insert pinion assembly into measuring device and not indicator reading (example: 1.50 mm).

2) Now note adjustment value engraved on pinion shaft in tenths of millimeters (example: +20 = +.20 mm). Now from value measured above, add adjustment value if plus and subtract value if minus. example: 1.50 + .20 = 1.70 mm). Insert gauge block holder into axle housing and screw on gauge block. Insert dial gauge holder 108 589 01 23 00 part 10 into adjusting gauge 108 589 01 23 00 part 19 and zero indicator with stem depressed about .12" (3 mm).

3) Insert adjusting device 108 589 01 23 00 together with dial gauge holder into axle housing. Make sure that stop of adjusting device, with its installed magnets, rests against axle housing and that housing contact surface is free of paint and dirt. Read indicator reading difference between adjusting gauge and gauge block face end. If value is plus, it must be subtracted from result obtained in step 2) and if minus, must be added to above result (example: If measured deviation is + .16 mm, subtract this value from 1.70 mm to obtain 1.54 mm). This result is thickness required shim for all axle ratios except 2.82:1 and 3.27:1.

4) On 2.82:1 axles, an additional 2.00 mm must be subtracted from result obtained in step 3) to arrive at final shim thickness. On 3.27:1 axles, subtract 1.50 mm from result obtained in step 3) to arrive at final shim thickness. Remove all tools from axle housing. Insert calculated shim into axle housing. If necessary, a thicker washer may be ground down to required thickness. Install outer races of bearing in housing using suitable tool (111 589 12 61 00).

5) Lubricate bearings on drive pinion with hypoid gear oil. Insert pinion and new collapsible spacer into housing and install front bearing inner race using suitable tool (111 589 12 61 00). Coat new seal on circumference with sealing compound and press into cover using suitable mandrel (111 589 12 61 00). Coat cover at contact surface with sealing compound and attach to axle housing. Coat running surface of flange with molybdenum disulphide paste and install flange using suitable tool (111 589 12 61 00).

Pinion Bearing Preload - 1) Check that runout of pinion flange does not exceed .001" (.03 mm). If runout is excessive, reposition flange on pinion until runout is to specifications or replace flange. Attach suitable holding wrench (111 589 00 13 00) to flange and screw on slot nut with lock washer. Gradually tighten slot nut while applying light blows against axle housing until torque required to rotate pinion is 12.2-13.9 INCH lbs. (14-16 cmkg) with new bearings or 4.3-8.7 INCH lbs. (5-10 cmkg) with used bearings.

2) Use care not to exceed specified preload. If preload is exceeded, remove pinion from housing and replace collapsible spacer. When specified preload is obtained, make not of torque value for later use. Reinstall adjusting device 108 589 01 23 00 part 05 with dial gauge holder 108 589 01 23 00 part 10 into axle housing and check pinion depth. Reading should be 66.00 mm (67.5 mm on 3.27:1 axle or 68.0 mm on 2.82:1 axle) plus or minus valve engraved on pinion. Maximum error is +.20 mm. If error exceeds this value, pinion must be reshimed and preload reset using new collapsible spacer peening lock plate in flange.

Backlash & Side Bearing Preload - 1) Insert old shim into left support tube bearing flange and install outer race of bearing using suitable mandrel (108 589 00 43 00). Screw threaded ring for adjusting bearing into axle housing about three turns. Press outer race of bearing into axle housing against stop at threaded ring using mandrel. Insert differential case into housing and install bearing flange with left support tube.

2) Screw in threaded ring on bearing in housing by means of suitable socket wrench (108 589 00 07 00) and tighten to a torque of about 25 ft. lbs. (3.5 mkg). Apply several blows with plastic hammer against housing to assist in seating bearings. CAUTION - If tightening threaded ring shows there is no more clearance between ring and pinion gears, back off threaded ring immediately, disassemble rear axle and install thinner shim, then repeat process.

3) Insert measuring device (108 589 03 23 00) into bore of differential and attach dial indicator. ATtach back square to axle housing. Measure backlash at four points with reference to circumference of ring gear by moving dial indicator holder as required. Backlash should be .0063±.008" (.16±.02 mm). If backlash is too high, install a thicker shim. If too low, install a thinner shim. A .004" (.1 mm) change in shim thickness will cause a .003-.004" (.1 mm) change in shim thickness will cause a .003-.004" (.08-.1 mm) change in backlash.

4) Run a tooth contact pattern test and correct as necessary. Readjust bearing preload by tightening or loosening threaded ring until torque required to rotate drive pinion is 17.4-21.7 INCH lbs. (20-25 cmkg) or at least 6.9 INCH lbs. (8 cmkg) over torque required to rotate pinion alone (see step 2) of "Pinion Bearing Preload"). CAUTION - If threaded ring has been screwed out, remove left support tube and remove differential case. Use mandrel to apply several blows against bearing outer race for perfect contact against threaded ring.

Final Inspection and Assembly - 1) Remove left support tube and coat sealing surface with sealing compound and install and tighten bolts. Recheck backlash and torque of entire assembly one more time. Secure threaded ring in housing using one of five different lock plates with tabs set in different locations. Attach selected lock plate and bend at both screw heads.

2) Install slide joint. Attach right support tube and axle suspension carrier to housing. Install both axle shafts and mount struts. Install brake shoes for hand brake and attach brake roller and caliper. Screw in oil cooling pipe and fill axle with oil.

Advertisement:

0 comments:

Post a Comment

Note: Only a member of this blog may post a comment.