DESCRIPTION

Rear axle is a semi-floating integral carrier type. Axles are carried by ball bearings located on outer ends of each axle shaft. Removable housing cover permits inspection and service of differential. A breather fitting is located on top of the right axle tube.

AXLE RATIO & IDENTIFICATION

Opel uses only one basic type of axle assembly. Any differences in Removal & Installation or Overhaul procedure will be noted where they occur. To determine axle ratio, divide number of ring gear teeth by number of pinion gear teeth.

REMOVAL AND INSTALLATION

AXLE SHAFT AND BEARINGS

Removal - Raise and support rear of vehicle and remove wheel and brake drum. Unscrew rear axle shaft retaining plate. Using suitable axle shaft puller (J-8805) and slide hammer (J-2619) on axle flange, remove axle shaft. To remove bearing, cut off retaining ring using a chisel. Press off bearing using a suitable remover (J-22912).

Installation - Check radial runout of axle shaft at ball bearing seat and lateral runout of axle shaft flange near largest diameter. If axle shaft exceeds specifications for runout or is otherwise damaged, it must be replaced. Using suitable installer tool (J-21694-1), press on bearing so that oil seal groove on bearing faces shaft splines. Using an installer ring, press on retainer ring so that shoulder faces bearing.

AXLE ASSEMBLY

Removal and Installation - Raise rear of vehicle and remove rear wheels and one brake drum. Disconnect parking brake components, lower shock absorber mounts, left end of track rod and stabilizer bar shackles (if equipped). Disconnect universal joint from pinion flange and support or tie propeller shaft out of way after marking for reassembly. Disconnect brake lines. Lower axle assembly far enough to remove coil springs. Remove central support bracket and disconnect lower control arms. Remove axle assembly. To install, reverse removal procedure.

OVERHAUL

DISASSEMBLY

NOTE - Overhaul may be accomplished with axle assembly installed in vehicle.

Case Assembly - 1) Remove differential cover bolts and allow lubricant to drain. Disconnect left end of track rod and tie out of way. Remove rear wheels and brake drums. Remove axle shafts as previously described. Check and record ring gear backlash.

2) Mark differential side bearing caps and carrier so that caps can be reinstalled in original positions. Remove bearing caps. Using two wooden hammer handles, pry differential case assembly from carrier. Do not drop or interchange side bearing outer races. Insert suitable adapter (J-2241-11) in bearing hub and remove side bearings using suitable puller (J-22599) with adapter leg (J-22929)

3) Remove differential case-to-ring gear bolts and top ring gear off case using soft faced hammer. Remove differential pinion shaft retaining pin using a suitable pin punch. Remove pinion shaft, gears, side gears and thrust washers.

Drive Pinion - Remove torque tube assembly. Using suitable tool (J-229-32), hold barrrel spline and remove pinion preload nut. With the aide of above tool, remove barrel spline from drive pinion and remove pinion by tapping rearward with a soft face hammer. Remove rear pinion bearing using suitable tool (J-22912) and remove pinion bearing outer races using a brass drift.

|

| Fig. 1 Exploded View of Opel Rear Axle Assembly |

REASSEMBLY AND ADJUSTMENT

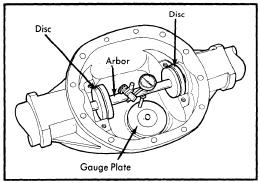

|

| Fig. 2 Pinion Gauge Plate Installation |

NOTE - Prior to reassembly, all parts should be cleaned and inspected for imperfections.

Pinion Depth and Bearing Prelaod - 1) To determine the correct pinion depth setting, use the following procedures. Make sure all gauge parts are clean. Lubricate front and rear pinion bearings and position them in carrier. Thread stud (J-21772-43) into gauge plate (J-23597-22). Holding bearings in place, install gauge plate and stud assembly on rear pinion bearing, then install pilot (J-23597-21) on front pinion bearings.

2) Install nut on stud. Hold stud stationary with wrench and tighten nut until a reading of 20 INCH Lbs. is obtained when rotating gauge plate assembly with torque wrench.

3) Install discs on gauge shaft assembly, then position assembly in carrier so dial indicator rod is centered on gauge block and discs are seated in side bearing bores. Install bearing caps and tighten bolts to 35 Ft. lbs.

|

| Fig. 3 Gauge Shaft Assembly Installed in Carrier |

4) Set dial indicator at ZERO, then place on mounting post of gauge shaft with contact button touching the indicator pad. Push dial indicator down until needle rotates approximately 3/4 turn clockwise, then tighten indicator.

5) Rotate gauge shaft slowly back and forth until dial indicator shows the greatest deflection. At this point set indicator to ZERO. Repeat this operation to verify setting.

6) Now rotate gauge shaft until dial indicator rod does not tough gauge block and record reading at this point. The dial reading will show the thickness of the shim to be installed.

7) Select correct pinion shim in the following manner: Note number stamped on the head of drive pinion. This number indicates the necessary change in pinion mounting distance. If the number is plus, decrease the shim thickness. If the number is minus, increaes the shim thickness. No number indicates the pinion is nominal.

|

| Fig. 4 Pinion Gear Reference Number |

8) After establishing the correct pinion number, convert the figure from hundredth millimeters to inches. If the number is plus, subtract from the number arrived at in step 7). If the number is minus, add to the number in step 7). Use the Pinion Depth Code number chart to select the proper shim(s)

9) Remove all measuring tools, then place shim(s) on drive pinion. Press rear pinion bearing onto pinion using suitable installer J-21022.

10) Lubricate pinion bearings and assemble drive pinion collapsible spacer, front pinion bearing, oil deflector plate and barrel spline sleeve in differential carrier. Thread barrel spline sleeve installer (J-22938) onto drive pinion and draw spline sleeve onto pinion until there are sufficient threads of pinion protruding to install pinion preload nut. Do not use installer to adjust pinion preload.

11) Remove installer and install washer and pinion preload nut. Using suitable tool (J-22932) to hold barrel spline, tighten preload nut until specified preload torque is obtained. If preload specification is exceeded, replace collapsible spacer and adjust again. Use suitable tool (J-22931) to install a new pinion seal that has been soaked in rear axle lubricant.

|

| Fig. 5 Measuring Side Gear Play |

Differential Case - 1) Install side gears and thrust washers. Lubricate and install pinion gears 180 degrees apart, and rotate gears as an assembly until pinion gear bores are aligned with the pinion shaft bores in the case. Install pinion shaft.

2) Using a dial indicator, measure the amount of backlash between side gears and pinion gears. Hold one side gear stationary while making check. If backlash exceeds .003" (.008 mm), make adjustments with thrust washers. Thrust washers are available in thickness to decrease backlash or decrease washer thickness to increase backlash.

3) Install lock pin into pinion shaft and caulk pin end to prevent loosening. Install ring gear on case and tighten bolt to specification. Check lateral runout of installed ring gear. If runout exceeds .003" (.008 mm), check for dirt or burrs holding ring gear in cocked position or that bolts are evenly tightened.

Backlash & Side Bearing Preload - 1) Install side bearings using suitable installer (J-22919) and drive handle (J-8092) while supporting opposite side of case on pilot (J-2241-11) to prevent bearing damage.

|

| Fig. 6 Measuring Side Bearing Preload |

2) Position differential case assembly, less side bearing shims, into side bearing bores of carrier. Insert feeler gauges of sufficient thickness between each bearing outer race and carrier to remove all end play. Ensure feeler stock is pushed to bottom of bearing bores. Mount suitable dial indicator (J-8001) on carrier so indicator stem is at right angles to a tooth on ring gear. Adjuster feeler gauge thickness from side to side until ring gear backlash is to specifications.

3) With zero end play and correct backlash established, remove feeler gauges, determine thickness of shims required an add .002" (.05 mm) to each shim pack to provide side bearing preload. Remove case assembly and install shim packs with respective side bearing using suitable installer (J-22919), driver handle (J-8092) and pilot (J-2241-11). Position case assembly and outer races in carrier. Use a soft faced hammer to drive case into carrier until side bearing outer races bottom in their bores.

4) Install side bearing caps in their original locations and tighten bolts. Rotate case assembly several times to seat bearings. Check backlash and preload using a torque wrench on ring gear attaching bolt. If torque is not correct, it will be necessary to re-shim side bearings. Install torque tube assembly and axle shaft.

4) Install side bearing caps in their original locations and tighten bolts. Rotate case assembly several times to seat bearings. Check backlash and preload using a torque wrench on ring gear attaching bolt. If torque is not correct, it will be necessary to re-shim side bearings. Install torque tube assembly and axle shaft.